Description

Automatic feeding hopper system is used in many farms in recent years. There are two types automatic feeding hopper machine. One is “A type feeding hopper” used on A type chicken cage. Another is “H type feeding hopper” used on H type chicken cage .Why poultry farmer choose automatic feeding hopper system , not the ceiling feeding machine , not the manual feeding? The reason is following:

With poultry farm develop much faster. The manual feeding can not satisfy the commercial farming requirement. Manual feeding is low efficiency , need a long time to give whole chicken feed. The chicken feed flour flow around when feeding, this will effect the worker’s health. Also manual feeding can not average feeding . At the same time , farmers are very tired for the whole days work.

So more and more poultry farmer choose automatic feeding hopper system for chicken breeding. Because the feeding hopper have the advantage: (1) High efficiency. Give chicken feed just need 5~8 minutes for whole chickens .(2)Labor saving. This can reduce cost on worker salary, also let the remaining worker liberate from no meaning job, spend more time learn breeding knowledge.(3)Average feeding. The automatic feeding hopper system can give feed automaticly, save chicken feed than manual feeding.

The Working Principle Of Automatic Feeding Hopper System

The oblique spiral conveyor lift chicken feed from silo or feed mill machine to the cross spiral conveyor. Then the cross spiral conveyor transport chicken feed to feeding hopper .After the every feeding hopper is full of chicken feed . The cross spiral conveyor will stop automaticly. Then press the button, the motor and reducer will drive chain. The chain drive the feeding hopper walk on chicken cage . When feeding hopper walking , it will give chicken feed. Under every feeding hopper there is average device , which will keep giving chicken feed average. The feeding hopper system can move back and forth.

Parameters Of Automatic Feeding Hopper System

The following data for your reference. More details or customized , please contact us

Electricity Source: AC, 3 phase

Power: 0.75kw~1.5kw

Voltage: 220V/380V

Size/set: (2.3~2.7)m*(0.8~1.5)m*(1.5~3.4)m L*W*H

Size/hopper: 0.66m*0.26m*0.5m L*W*H

Capacity/hopper: 35~90kg

Working rate: 1.25kg~5.85kg/12meter (this is adjustable )

Walking Speed: 8~12m/min

Weight/set: 100~600kg

Guide rail: thickness=3.5mm, diamater=50mm

Guide rail material: hot galvanized carbon steel.

Spiral Conveyor(Augur convenyor): Diameter=75mm to 150mm

Feed silo: 5t , 10 t, 15t, 20t

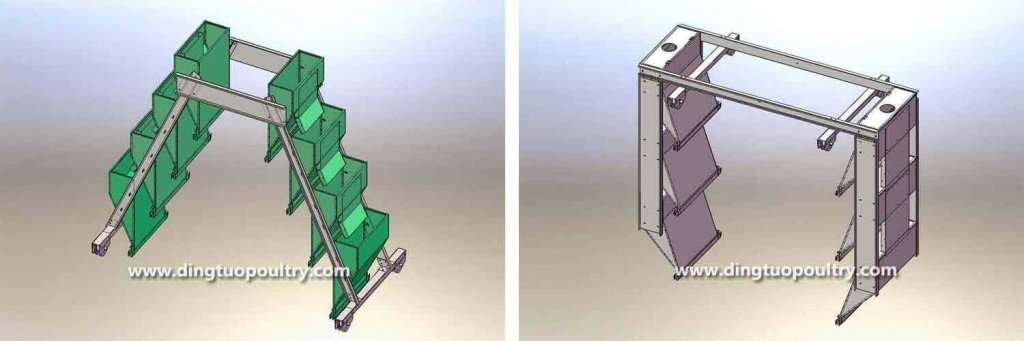

(Design draft for automatic feeding hopper)

( A type feeding hopper used in chicken farm )

( H type automatic feeding hopper used on chicken farm )

( Accessories)

We have favorable policy and price for different products & projects during different period every year, email us to steven@dingtuopoultry.com for talking more specific details please!!!

You can also choose “Leave Your Message To Us” in the following

Leave Your Message To Us (we will reply as soon as we see it )

|

Reviews

There are no reviews yet.